With over two decades in business – spanning strategy consulting, tech startups and executive leadership – I am committed to helping your organization thrive.

At Reliability, we’re on a mission to help enhance strategic decision-making and operational excellence through the power of Root Cause Analysis, and I hope this article will be helpful!

Our goal is to help you better understand common mistakes in RCA by offering insights and practical tips based on years of experience. Whether you’re new to doing RCAs or a seasoned pro, we trust this will be useful in your journey towards working hard and working smart.

Root Cause Analysis (RCA) is a systematic process used by engineers and reliability experts to identify the underlying reasons for failures or problems. Its importance in problem-solving cannot be overstated, as it helps prevent the recurrence of issues by addressing their origins rather than just treating symptoms.

Here are some common mistakes in Root Cause Analysis and ways to avoid them:

Mistake 1: Inadequate Problem Definition

A poorly defined problem statement is a significant hindrance in RCA. Vague or overly broad problem statements lead to ineffective analysis. Precision in defining the problem sets a clear direction for the analysis.

How to avoid inadequate problem definition?

To avoid inadequate problem definition, invest time in clearly articulating the problem. Use specific, measurable terms and ensure that the problem statement is neither too broad nor too vague. This might involve gathering preliminary data or consulting with stakeholders to gain a comprehensive understanding of the issue.

Mistake 2: Focusing on Symptoms

Another frequent error is concentrating solely on the symptoms of a problem rather than digging deeper to uncover the underlying causes. This superficial approach might provide a quick fix but fails to prevent the issue from recurring. A more effective strategy involves a detailed examination of the problem to understand its fundamental causes.

How to avoid focusing on symptoms?

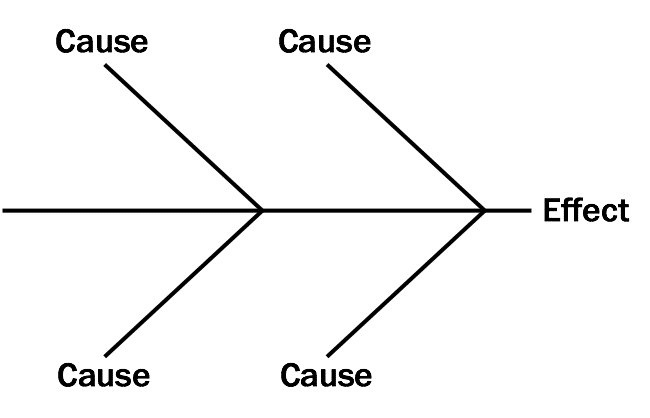

To prevent focusing solely on symptoms, employ techniques like the “5 Whys” method and Fishbone Diagram, which encourages deeper investigation into the underlying causes of a problem. This approach helps in moving past immediate symptoms and identifying the root causes.

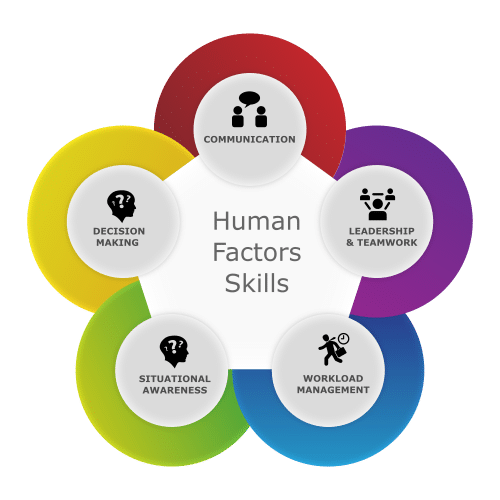

Mistake 3: Ignoring Human Factors

Human factors often play a significant role in the occurrence of problems, yet they are frequently overlooked in RCA. Factors such as human error, training deficiencies, and ergonomic issues can be crucial in understanding why a problem occurred. Acknowledging and addressing these human elements is vital for a comprehensive analysis.

How to avoid ignoring human factors?

Acknowledge the role of human factors in problems by conducting thorough interviews and observations. Consider aspects like training, workload, human error, and ergonomic factors. Incorporating human factors analysis tools, such as Human Error Analysis (HEA) or Human Factors Analysis and Classification System (HFACS), can be beneficial.

Mistake 4: Overlooking External Factors

External factors, such as environmental conditions, market dynamics, or supply chain disruptions, can significantly impact the root cause of a problem. Failing to consider these external elements can lead to an incomplete analysis and ineffective solutions.

How to avoid overlooking external factors?

Ensure that your analysis includes external factors such as market trends, environmental conditions, and supply chain issues. This can be achieved by conducting a PESTLE analysis (Political, Economic, Social, Technological, Legal, and Environmental) to understand external influences.

Mistake 5: Stopping at One Cause

Many problems are the result of multiple contributing factors. Settling on a single cause too early in the RCA process can lead to partial solutions that don’t address the entire scope of the problem. It’s important to explore all potential causes and their interrelationships.

How to avoid overlooking other causes?

Recognize that problems often have multiple causes. Use tools like fishbone diagrams or fault tree analysis to map out various contributing factors and their interrelationships. Avoid settling on a single cause too early in the process.

Mistake 6: Failing to Implement or Monitor Solutions

Identifying the root cause and devising solutions is only part of the process. Failing to implement these solutions effectively or to monitor their impact can render the entire RCA process futile. It’s crucial to ensure that solutions are not only implemented but also monitored for their effectiveness over time.

How to avoid failing to implement or monitor solutions?

After identifying solutions, create a detailed implementation plan. This plan should include timelines, responsibilities, and resources required. Once implemented, continuously monitor the effectiveness of these solutions through key performance indicators (KPIs) and regular reviews.

Mistake 7: Jumping to Conclusions

One of the most common mistakes in RCA is making assumptions and jumping to conclusions without thorough investigation. This approach often leads to incorrect identification of the root cause, resulting in ineffective solutions. It’s essential to gather comprehensive data and analyze it objectively before drawing any conclusions.

How to avoid jumping to conclusions?

To prevent premature conclusions, gather comprehensive data and analyze it objectively. Avoid relying on assumptions or anecdotal evidence. Utilize data analysis tools and techniques to ensure that conclusions are based on solid evidence.

Here’s What Else to Consider

To improve RCA techniques, consider using and streamlining various root cause analysis tools and methods, such as fishbone diagrams, the 5 Whys, and failure mode and effects analysis (FMEA). Engaging in regular training and staying updated with best practices in RCA can also enhance your skills and effectiveness.

EasyRCA is designed to streamline and enhance the Root Cause Analysis (RCA) process, addressing many of the common mistakes highlighted in the article. It encourages a systematic approach to data collection and analysis. By providing structured templates and workflows, it guides users through a step-by-step process, reducing the likelihood of jumping to conclusions without sufficient evidence. This holistic approach ensures that all possible contributing factors are considered in the analysis.

Avoiding these common mistakes in root cause analysis is crucial for engineers and reliability experts. By focusing on thorough data collection, considering all potential causes, including human and external factors, and effectively implementing and monitoring solutions, professionals can significantly improve their problem-solving outcomes. Remember, effective RCA is not just about finding a cause; it’s about uncovering the right cause and ensuring sustainable solutions.

I hope you found this guide to avoid common mistakes in RCA insightful and actionable! Stay tuned for more thought-provoking articles as we continue to share our knowledge. Success is rooted in a thorough understanding and consistent application, and we hope this article was a step in unlocking the full potential of Root Cause Analysis for your organization.

Reliability runs initiatives such as an online learning center focused on the proprietary PROACT® RCA methodology and EasyRCA.com software. For additional resources, visit EasyRCA Resources.

Ignite your curiosity, subscribe now!

Stay informed and connected with the latest updates by subscribing today!

Recent Comments