With over two decades in business – spanning strategy consulting, tech startups, and executive leadership – I am committed to helping your organization thrive.

At Reliability, we’re on a mission to help enhance strategic decision-making and operational excellence through the power of Root Cause Analysis, and I hope this article will be helpful!

Our goal is to help you better understand real-life case studies of reliability improvement by offering insights, case studies, and practical tips based on years of experience. Whether you’re new to doing root cause analyses or a seasoned pro, we trust this will be useful in your journey towards working hard and working smart.

———————

Once upon a time, in the bustling world of pulp and paper production, International Paper stood tall as a leading global producer of renewable fiber-based packaging, pulp, and paper products. With a commitment to innovation and excellence, they embarked on a journey to refine their reliability engineering practices. To achieve this, they sought the help of EasyRCA, a cutting-edge software solution designed to enhance the effectiveness of Root Cause Failure Analysis (RCFA). This is the story of how International Paper integrated EasyRCA into their operations and reaped significant benefits.

The Catalyst for Change

In the heart of International Paper’s operations, Scott Wiebold was a name synonymous with reliability. With over 26 years in the industry, Scott had seen it all. As the Root Cause Failure Analysis Subject Matter Expert, he had dedicated his career to improving reliability across the organization. His passion for RCFA and continuous improvement was a driving force, leading him to search for more efficient tools and methodologies to elevate the company’s practices.

A Time of Challenge

Before the arrival of EasyRCA, International Paper’s RCFA processes were fraught with challenges. The existing tools, such as Visio and Excel, were cumbersome and time-consuming, causing frustration among the staff. The inefficiency of managing evidence and building logic trees across separate programs led to widespread reluctance to fully embrace RCFA methodologies. The complexities and time constraints hindered many employees from utilizing RCFA for all potential use cases.

A Ray of Hope

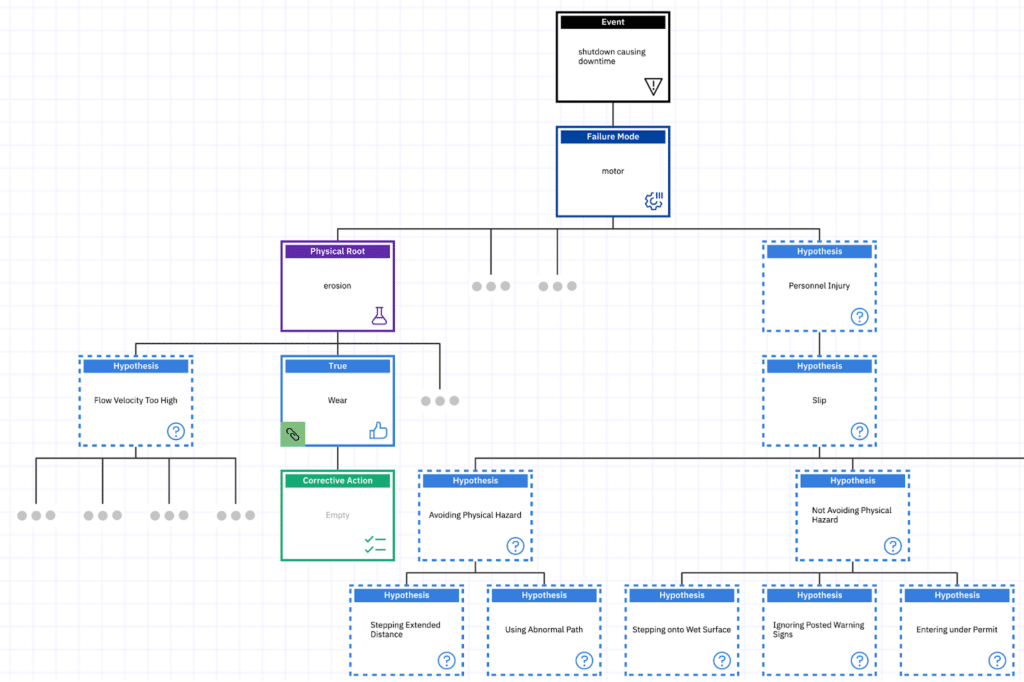

Enter EasyRCA, a comprehensive solution that promised to transform these challenges into opportunities. This user-friendly platform integrated all necessary functionalities, allowing seamless creation and management of logic trees, evidence collection, and task assignments. The potential to streamline the RCFA process was immense.

The Journey of Implementation

The implementation of EasyRCA at International Paper was a carefully crafted journey. It began with initial training sessions conducted by the Reliability Center Inc., followed by internal training led by Scott himself. Clear communication of EasyRCA’s benefits and functionalities was crucial in gaining the team’s buy-in. Support systems and materials for ongoing training and troubleshooting were established, ensuring the sustainability of this new approach.

The Fruits of Labor

As EasyRCA took root within International Paper, the benefits became apparent. The quality of RCFA improved significantly, with more comprehensive and accurate identification of root causes. The integrated platform saved time and reduced workload, enabling more employees to engage in RCFA. The user-friendly interface encouraged its use beyond mechanical failures, extending to safety, environmental, and operational issues.

Real-World Impact

International Paper began to witness the real-world impact of EasyRCA through various applications. Safety incidents were analyzed with greater precision, leading to better preventive measures. Environmental problems were identified and resolved more efficiently. Operational efficiency improved as potential equipment failures were proactively addressed before they could disrupt production.

A Vision for the Future

Scott’s vision for the future of IP, is helping the team at EasyRCA prioritize updates and enhancements, such as AI-driven features that could automatically generate hypotheses for common equipment failures. These advancements promise to further streamline the RCFA process and empower new engineers, even those with less experience, to perform high-quality analyses.

A New Dawn

The integration of EasyRCA at International Paper marked a new dawn in their RCFA processes. It transformed their approach to reliability, leading to significant improvements in efficiency and overall operational excellence. This tale of innovation and dedication underscores the importance of adopting advanced tools and methodologies to stay ahead in the competitive landscape of the pulp and paper industry. And so, with EasyRCA as their trusted companion, International Paper continued to lead the way, ever committed to reliability and excellence.

___________

I hope you found this case study insightful and actionable! Stay tuned for more thought-provoking articles as we continue to share our knowledge. Success is rooted in a thorough understanding and consistent application, and we hope this article was a step in unlocking the full potential of Root Cause Analysis for your organization.

Reliability runs initiatives such as an online learning center focused on the proprietary PROACT® RCA methodology and EasyRCA.com software. For additional resources, visit EasyRCA Resources.

Ignite your curiosity, subscribe now!

Stay informed and connected with the latest updates by subscribing today!