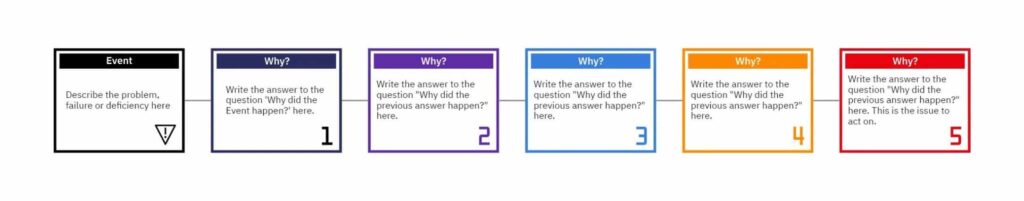

Introduction to the 5 Whys Root Cause Analysis

The 5 Whys Root Cause Analysis is a brainchild of Sakichi Toyoda, a prominent Japanese industrialist, and the founder of Toyota Industries. Conceived in the early 20th century, it was designed as a core component of the Toyota Production System to enhance operational efficiency.

This straightforward yet robust technique is all about asking “Why?” five times to unearth the root cause of a problem. It aligns with Toyota’s ‘go and see’ philosophy, underscoring that real-world understanding should guide decision-making, not detached assumptions.

This method is particularly effective when the answers are drawn from those with hands-on experience. It starts with identifying a problem, delving into its depths with repeated questioning, and then, devising and applying a preventative counter-measure. Today, the 5 Whys method remains a widely employed problem-solving strategy, resonating with its commitment to in-depth understanding and continuous improvement.

TL,DR;

- The ‘5 whys’ method is a problem-solving technique that involves asking “Why?” five times to uncover the root cause of a problem.

- It emphasizes the importance of real-world understanding over assumptions and aligns with Toyota’s ‘go and see’ philosophy.

- The method involves cross-functional teams to ensure a comprehensive perspective when identifying the root cause.

- The process of conducting a 5 Whys root cause analysis includes defining the problem, asking “Why?” five times, identifying the root cause, developing and implementing a solution, and monitoring the results.

- The 5 Whys root cause analysis is best suited for straightforward problems with clear causality, but may not be as effective for complex issues with multiple root causes. It promotes a culture of critical thinking, continuous improvement, and long-term solutions.

What is the 5 Whys Root Cause Analysis?

The 5 Whys method is a simple yet powerful tool used for problem-solving and root cause analysis. It’s centred on the principle of asking the question “Why?” five times to delve into a problem and identify its root cause. The aim is to get past the symptoms and reach the fundamental origin of an issue.

The idea behind the 5 Whys method is not to just stop at the first answer you receive but to continue asking “Why?” until you’ve peeled back the layers of a problem. This iterative questioning approach is designed to dive deeper into the details of a situation and identify the root cause, rather than merely addressing the immediate, surface-level symptoms.

The number ‘5’ in the technique’s name is somewhat arbitrary – the key is to keep asking “Why?” until you’re confident that you’ve discovered the true root cause. In some cases, you may find the root cause in fewer than five questions, while in others, it may take more than five. The number is not as important as the logic behind the method, which is to promote deep, systemic thinking rather than settling for quick-fix solutions.

An essential aspect of the 5 Whys root cause analysis approach is that it involves cross-functional teams. People from different areas of the organization participate in the process, which ensures a comprehensive perspective is considered when identifying the root cause. This collective problem-solving process can lead to buy-in from various stakeholders, and it aids in ensuring that the implemented solutions are more effective and long-lasting.

TIPS:

We often find ourselves battling fires, metaphorically speaking. But the 5 Whys Method empowers us to become a fire prevention specialist. Instead of constantly extinguishing problems as they arise, we use this method to identify the root causes and design robust systems that prevent fires from igniting in the first place. Therefore, it’s not just about heroics; it’s about building structures that withstand the heat.

Why Use the 5 Whys Root Cause Analysis?

The elegance of the 5 Whys root cause analysis lies in its simplicity and effectiveness. It’s a tool that promotes a culture of critical thinking, empowers employees at all levels, and helps foster a continuous improvement mindset. Instead of applying band-aid solutions to problems, it encourages digging deeper to eliminate issues from their roots, leading to long-term improvement and growth. It is not only a problem-solving tool but also a vehicle for organizational learning and development.

TIPS:

When applying the 5 Whys method, encourage a diverse team to participate. Different perspectives and experiences can lead to more comprehensive, innovative solutions and long term improvement, helping you address the underlying issues more effectively.

When to Use the 5 Whys Root Cause Analysis?

Implementing the 5 Whys root cause analysis is typically best when dealing with problems that require a single corrective measure. It is highly effective when dealing with uncomplicated issues with clear, linear causality. Businesses use the 5 Whys method for troubleshooting, quality improvement, and problem-solving. It’s often the tool of choice when you need quick, straightforward solutions, making it suitable for fast-paced environments or situations where resources for complex problem analysis may be lacking.

In situations where there’s a recurring problem, the 5 Whys root cause analysis can help reveal whether there’s a fundamental issue that hasn’t been addressed yet. By peeling back the layers of symptoms, one might uncover a core problem that, when fixed, prevents the issue from recurring. It can be especially beneficial in helping teams identify a problem’s root cause, which they might overlook otherwise.

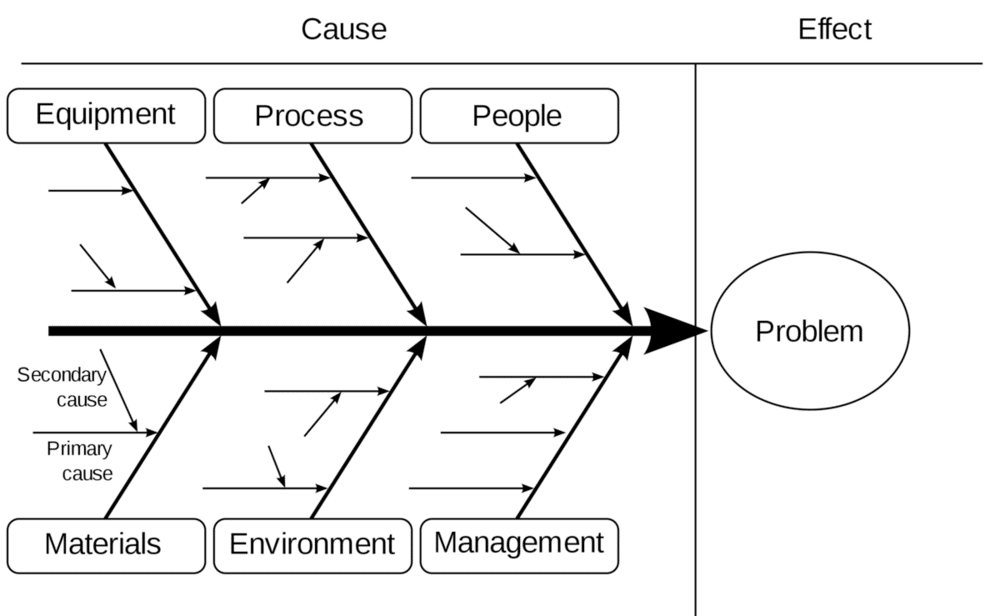

However, it’s crucial to understand that not every problem lends itself well to this methodology. The 5 Whys method is less effective in dealing with complex problems where there are multiple root causes. In these instances, combining it with other tools like the Failure Mode and Effects Analysis (FMEA) or Fault Tree Analysis (FTA) might offer a more comprehensive perspective for problem-solving. For a broader perspective on additional tools and approaches beyond 5 Whys, explore these 7 powerful root cause analysis techniques to tackle various problem scenarios.

How to Conduct a 5 Whys Root Cause Analysis?

Conducting a 5 Whys analysis can be distilled into a simple, step-by-step process. Here is how you could perform a through 5 why analysis:

- Define the Problem: Start by clearly articulating the problem. This should be specific, observable, and measurable to ensure everyone is on the same page about what the issue is. It’s important to focus on facts rather than assumptions or interpretations.

- Ask the First ‘Why‘: Begin by asking ‘Why’ the problem has occurred. Search for an immediate cause that directly led to the problem. This forms the first layer of the problem. Make sure that your answer is based on facts, not assumptions.

- Ask the Next ‘Why’ Based on the First Answer: The answer to the first ‘Why’ becomes the starting point for the next question. Ask ‘Why’ the first cause occurred. This leads to a deeper layer of the problem and brings you closer to the root cause.

- Repeat the Process Three More Times: Continue this process, always using the last answer to form the next ‘Why’ question, until you’ve asked ‘Why’ five times in total. This will generally help you to reach the underlying root cause of the problem. Remember, the aim is not to place blame but to identify the process or system that failed.

- Identify the Root Cause(s): By the fifth ‘Why’, you should be able to identify the root cause(s) of the problem. This is the fundamental issue that set everything else into motion. It might not be the most obvious cause, but it is the one that, if addressed, will prevent the problem from recurring. Using RCA software like EasyRCA can be very helpful in the 5 WhyRCA process.

- Develop and Implement a Solution: Now that you’ve identified the root cause, you can develop a plan of action to address it. The solution should directly address the root cause and should be practical and achievable. Once the plan is developed, implement it and monitor the results over time.

- Monitor the Results: After the solution is implemented, continue to monitor the situation to ensure that the problem has been resolved. If the problem recurs, go back through the Five Whys process to see if there might be a different or additional root cause that was not identified in the first analysis.

Remember, the Five Whys analysis is an iterative process, and it requires open and honest communication. It’s a powerful tool for learning and improvement, but it works best in a blame-free environment where the focus is on improving processes and systems rather than pinpointing individual errors.

Example of a 5 Whys Root Cause Analysis

This is an example of how the 5 Whys root cause analysis could be used to help find a root cause:

| Step | Question | Answer |

| 1 | Why did the customer receive their delivery late? | The package was dispatched late from our warehouse. |

| 2 | Why was the package dispatched late from our warehouse? | The package wasn’t packed on time. |

| 3 | Why wasn’t the package packed on time? | The order for packing the package was not issued until late. |

| 4 | Why was the order for packing the package issued late? | The order information from the sales department to the warehouse was delayed. |

| 5 | Why was the order information from the sales department to the warehouse delayed? | The sales department did not enter the order into the system on time. |

Upon reviewing the 5 Whys, the solution became clear:

- The root cause for the late delivery is that the sales department didn’t enter the order into the system on time.

- The solution typically involves implementing (or improving) a procedure that ensures orders are entered promptly. For example, the sales team might adopt a mandatory same-day data entry policy, use automated reminders, or implement a system that triggers an alert if an order hasn’t been entered within a certain timeframe.

- The outcome of addressing this root cause is that orders reach the warehouse more quickly, enabling on-time packing and dispatch. Ultimately, this reduces delivery delays and improves customer satisfaction.

Common Mistakes/Pitfalls When Implementing the 5 Whys Method

Implementing the 5 Whys can be straightforward in theory, but many teams stumble over common pitfalls that undermine the process and skew outcomes. Below are the most frequent mistakes to watch out for:

- Stopping Too Soon

- One of the biggest errors is failing to push through all five “whys.” Teams may stop after two or three questions once they feel they have an answer. However, this often leaves hidden causes undiscovered. Commit to going the full distance, even if the answer feels obvious partway through.

- Assigning Blame Instead of Solving Problems

- The 5 Whys technique aims to uncover systemic or process-based issues, not to single out individuals. Pointing fingers can shut down open dialogue and discourage a thorough investigation. Keep the focus on the process, not the people.

- Asking ‘Why?’ Without Specifics

- Vague questioning can lead to equally vague answers. Try to ground each “why” in the actual data or evidence you’ve gathered. For example, instead of simply asking, “Why did production slow down?” specify the timeframe and context: “Why did the assembly line slow from 50 units per hour to 30 units per hour between 2 p.m. and 4 p.m. on Monday?”

- Lack of Documentation

- Failing to record each “why” and the corresponding answers makes it difficult to revisit the analysis later. Proper documentation not only serves as a reference but also helps track patterns if similar issues arise in the future.

- Not Validating the Root Cause

- Even after you arrive at a presumed root cause, it’s essential to validate and test potential solutions. Implementing a fix without confirming the cause leaves room for recurring problems or new issues down the line.

By avoiding these pitfalls, teams can stay focused on uncovering genuine root causes rather than mere symptoms or quick-fix solutions. The key is staying persistent, objective, and data-driven throughout every stage of the 5 Whys process. It is important to remember that although the 5 Whys root cause analysis method is a great way to resolve streamlined issues, the best practitioners would apply various root cause analysis methods when dealing with real-world problems with complex issues.

Unlocking Problem-Solving Potential with the 5 Whys Method

The 5 Whys technique is a highly efficient, straightforward tool that enables teams across industries to dig deep into the roots of a problem. When used correctly, it goes beyond simply treating the symptoms of a problem and aims to unearth the fundamental cause, paving the way for long-term, effective solutions. Not only does it foster an environment of collaboration and open discussion, but it also encourages a culture of continuous improvement and innovation.

We at Reliability understand the value of such effective problem-solving techniques, and through the consistent use of methods like the 5 Whys Method, we continue to uphold our commitment to delivering reliable, high-quality solutions that stand the test of time. Remember, in our quest for solving problems, it is not enough to skim the surface; diving deep is where true and lasting solutions lie.

Unlock the full potential of Root Cause Analysis with EasyRCA!

Simplify your RCA processes, gain actionable insights, and drive operational excellence. Sign up now to transform your problem-solving approach.

Ignite your curiosity, subscribe now!

Stay informed and connected with the latest updates by subscribing today!