What is Root Cause Analysis?

Root Cause Analysis, commonly abbreviated as RCA, is a systematic approach to identifying the main cause of a problem or failure. Instead of merely addressing the symptoms, RCA digs deeper, striving to uncover the underlying issues that are the real culprits. Think of it as a detective working tirelessly to solve a mystery, refusing to rest until the true perpetrator is found.

TL,DR;

- Root Cause Analysis (RCA) is a method for pinpointing the actual source of problems rather than just addressing symptoms. Imagine it as a detective work that drills deep into issues.

- It offers a proactive approach that prevents issues from recurring, thus saving time and resources. It is akin to fixing a leak at its source rather than continually wiping water away.

- RCA relies on a cause-and-effect framework. It uses various investigative tactics and data scrutinization to isolate root causes.

- The focus is on systems and processes, not on people. It recognizes that issues often spring from multiple sources and aims for solutions instead of blame.

- Multiple techniques exist, from simple ones like “5 Whys” to more complex ones such as PROACT, Pareto Charts and Fishbone Diagrams. Specialized software like EasyRCA can also aid in the process.

- RCA involves identifying the problem, gathering data, finding contributing factors, isolating the root cause, and then deploying solutions. Each stage is crucial for its success.

- RCA has proven effective in various fields like healthcare, manufacturing, and IT.

Why is Root Cause Analysis Essential?

Imagine you’re trying to solve a leak in your kitchen. Instead of simply wiping away the water each time, wouldn’t you prefer to find the source of the leak and fix it? That’s the rationale behind RCA. By identifying the root cause of a problem, organisations can implement long-term solutions, preventing recurrences and ensuring smoother operations. In essence, RCA promotes a proactive rather than a reactive approach, saving time, resources, and boosting overall efficiency.

How Does Root Cause Analysis Work?

At its core, Root Cause Analysis operates on a principle of causality. Every problem or failure has an origin, and RCA’s goal is to trace back to that origin. This involves a combination of investigative techniques, data analysis, root cause analysis training, and sometimes even a bit of intuition. Once the root cause is pinpointed, measures are taken to address it directly.

Principles of Root Cause Analysis

RCA is not about finding a scapegoat or assigning blame. It’s about understanding systems, processes, and the intricate web of interactions that can lead to issues. Here are some guiding principles:

- Systems and Processes, Not Individuals: Focus on how things work and where they can falter.

- Multiple Causes: Often, there’s more than one contributing factor.

- Solutions over Blame: The end goal is always solution-oriented, not finger-pointing.

What Are the Different Tools to Perform Root Cause Analysis?

Beneath the vast umbrella of RCA, several techniques shine bright, each offering unique insights in identifying root causes:

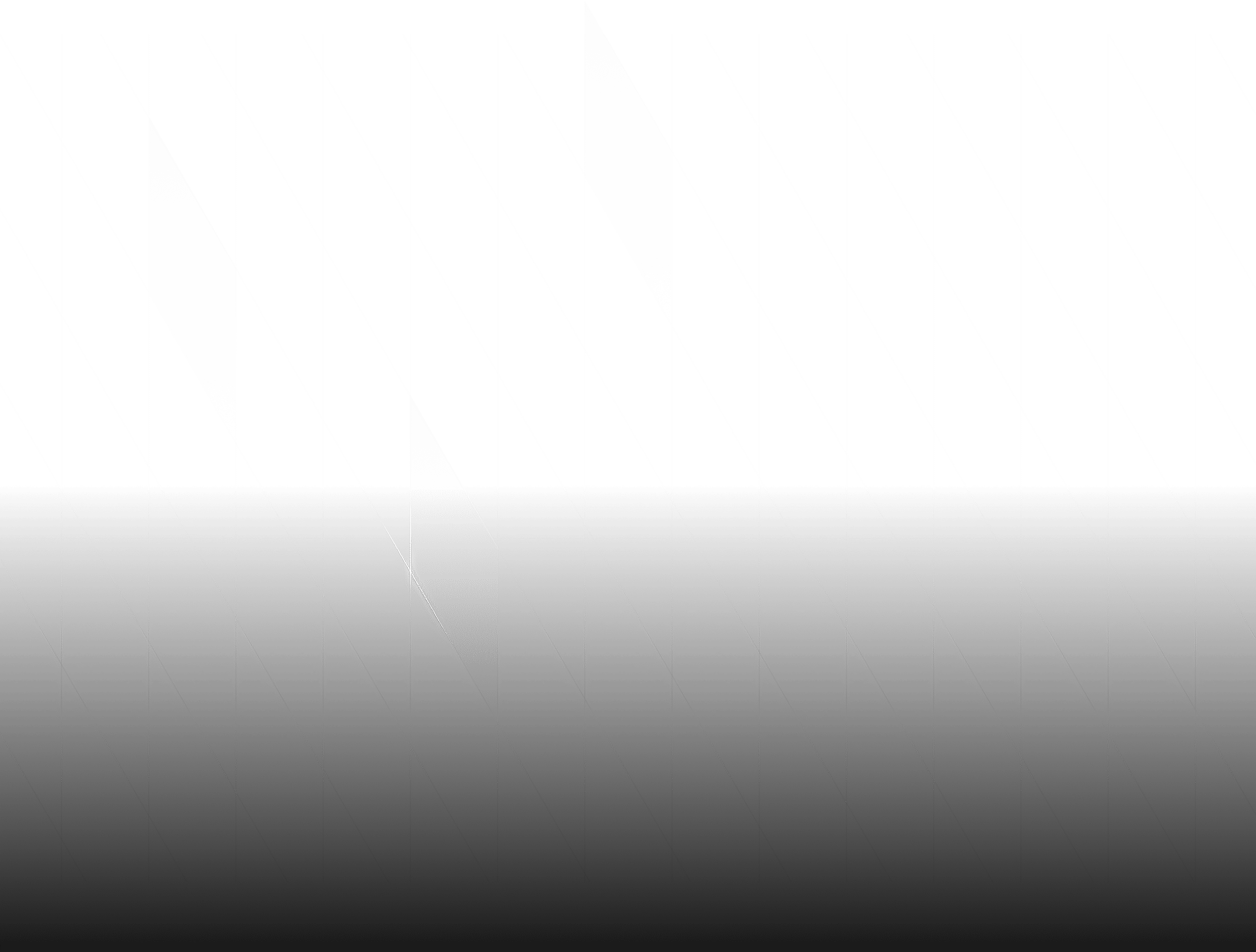

5 Whys Technique

A remarkably straightforward method, the 5 Whys involves asking “Why?” repeatedly (usually five times) until the core issue is identified. It’s a bit like a curious child, persistently inquiring until they get to the heart of the matter. This iterative questioning technique delves deep into problems, revealing their core causes. One of the great RCA software to perform 5 Why analysis is EasyRCA.

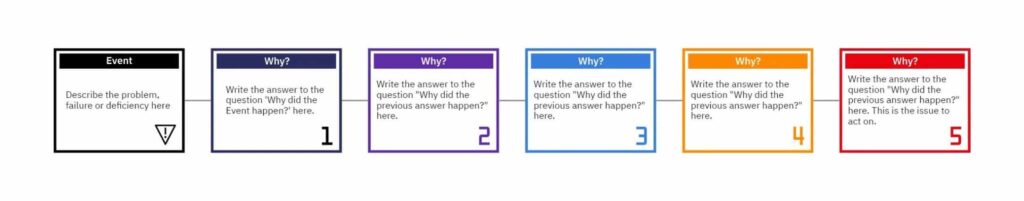

Fishbone Diagram (Cause-and-Effect Diagram)

Also known as the Ishikawa diagram, this technique visually maps out potential causes of a problem, branching out like the bones of a fish. It’s an excellent tool for brainstorming sessions, encouraging teams to explore every possible angle.

Pareto Chart

Based on the Pareto Principle (80/20 rule), this chart helps in identifying and prioritising the most significant factors in a set of data. It’s useful in cases where multiple potential causes exist, and there’s a need to focus on the most impactful ones.

Flowchart

A flowchart represents a process by detailing each step in sequence. By understanding the entire process, one can identify potential bottlenecks or points of failure that might be contributing to the main problem.

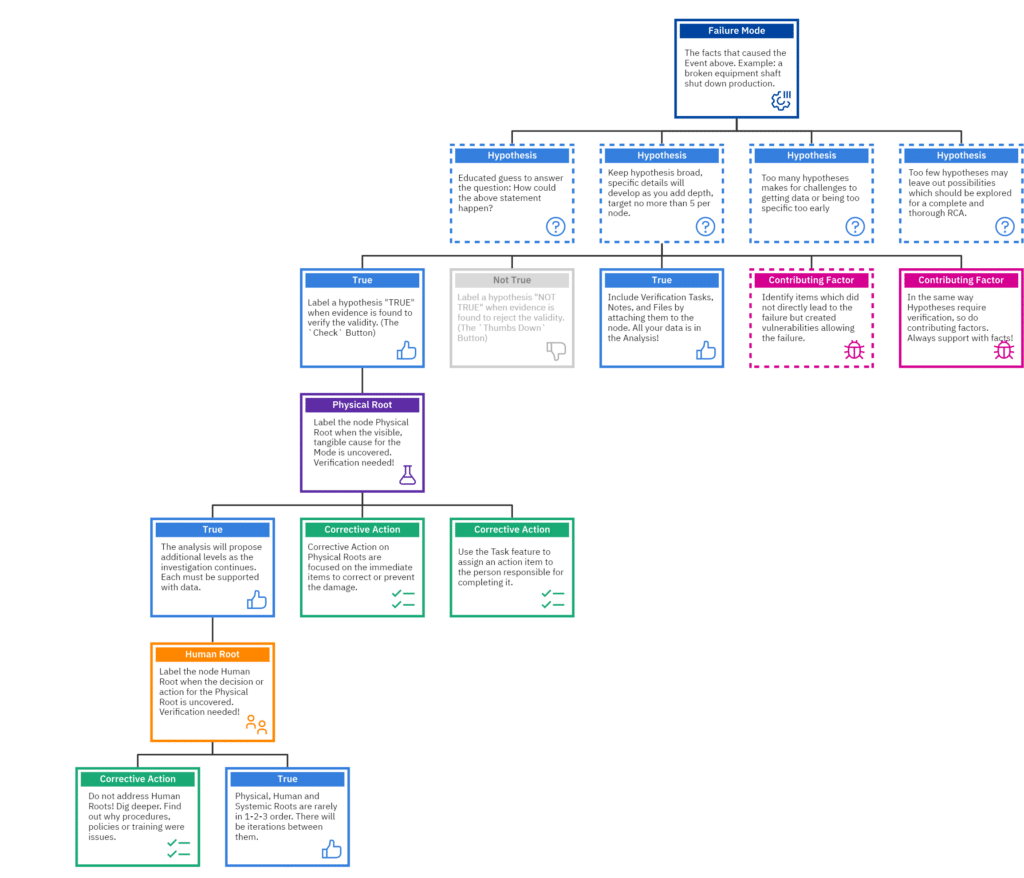

PROACT

PROACT® RCA is a robust Root Cause Analysis (RCA) process that can drive incredible business results for your company. Since its inception in the mid-80’s, the PROACT® RCA approach has helped hundreds of companies do tens of thousands of successful RCAs, resulting in large financial returns for the business.

TIPS:

From “5 Whys” to Fishbone Diagrams and Pareto Charts, various tools offer unique vantage points for uncovering root causes. Choose wisely, or even better, combine different methods for a more comprehensive analysis. Specialized software can also expedite the process, like EasyRCA for conducting 5 Why analyses.

What are the Stages of Conducting a Root Cause Analysis?

Conducting a robust RCA involves several key stages:

Identify the Problem:

This initial step is crucial. Clearly defining the problem ensures that you’re addressing the right issue, to begin with.

Data Collection:

Data provides the evidence needed to back up hypotheses. Whether it’s incident reports, logs, or user feedback, collecting comprehensive data ensures a more accurate analysis.

Identify Causal Factors:

These are factors that contribute to the problem but aren’t necessarily the root cause. Think of them as accomplices in our detective analogy.

Identify the Root Cause:

Beyond the techniques mentioned earlier, observational studies, simulations, and sometimes even experimental setups can help in nailing down the main culprit.

Implement Solutions:

Once the root cause is known, solutions should be carefully designed, tested, and then implemented. This stage often involves collaboration across teams and sometimes even external consultants.

TIPS:

Root cause analysis acknowledges that issues often arise from a different contributing factors. Therefore, do not limit yourself to finding just a single root cause. Explore the possibility that multiple elements may be interacting in unanticipated ways, compounding the issue at hand.

What are some of the real-life examples of RCA? (Case Studies)

The effectiveness of Root Cause Analysis (RCA) can be best illustrated by exploring real-world scenarios where its application led to groundbreaking solutions and enhancements.

Healthcare: Diagnosing Medical Errors

In a renowned hospital, there was a notable rise in post-surgical infections. The initial response was to enhance the sterilisation procedures, but the problem persisted. Through RCA, the team discovered that a batch of surgical gloves had microscopic tears, leading to contamination despite stringent sterilisation.

The gloves were promptly recalled, and additional quality checks were instated. Not only did the infections drop significantly, but the hospital also gained insights into bolstering its supply chain verification.

Manufacturing: Addressing Product Failures

A leading automobile manufacturer faced a crisis when their latest model had an unusually high rate of brake failures. Initially, they believed it was an assembly line error. However, an RCA revealed that the brake pads’ composite material, sourced from a new vendor, was not up to the required standards. Acting on this discovery, they reverted to their tried-and-tested material, initiated recalls, and introduced stricter vendor verification processes. This proactive approach saved the company millions in potential lawsuits and further recall costs, reinstating customer trust.

IT: Resolving System Downtimes

A global IT firm was grappling with recurrent server downtimes, disrupting their services and affecting their clients adversely. The initial thought was hardware malfunctions. However, RCA unveiled that a recent software update was incompatible with certain server components, causing them to overheat and shut down. The IT team quickly rolled back the software update, and in parallel, began a more comprehensive testing protocol for future updates. The outcome was a more resilient IT infrastructure and a re-established reputation for reliability.

Unlock the full potential of Root Cause Analysis with EasyRCA!

Simplify your RCA processes, gain actionable insights, and drive operational excellence. Sign up now to transform your problem-solving approach.

Ignite your curiosity, subscribe now!

Stay informed and connected with the latest updates by subscribing today!