Why You Need a Root Cause Analysis Template

A root cause analysis template gives teams a structured way to solve problems effectively and consistently. Instead of jumping to quick fixes, an RCA template helps you document issues, dig deeper into the real causes, and build corrective actions that prevent repeat failures.

Organizations across manufacturing, healthcare, IT, and services use RCA templates to capture problems in a consistent format, align teams, and ensure no critical details get overlooked. By standardizing the process, your business can save time, reduce costs, and strengthen reliability.

In this guide, you’ll learn step by step how to create a root cause analysis template that works for any industry and problem type—complete with examples, pro tips, and best practices.

What Is Root Cause Analysis (RCA)?

Root Cause Analysis is a systematic problem-solving process used to identify the underlying causes of issues, rather than just treating the symptoms.

For example:

- If a machine breaks down, the immediate fix might be to repair it.

- RCA digs deeper: Why did the machine fail? Was maintenance skipped? Did a part wear out earlier than expected?

By addressing the root causes of failures, organizations prevent costly recurrences, improve reliability, and strengthen long-term performance.

👉 Related resource: 5 Whys Root Cause Analysis

Why Use a Root Cause Analysis Template?

A root cause analysis template ensures that every RCA investigation follows a clear, structured process. Benefits include:

- Consistency: Everyone follows the same steps.

- Clarity: Clear fields prevent missed information.

- Collaboration: Teams can contribute without confusion.

- Accountability: Responsibilities and timelines are documented.

- Efficiency: Faster problem resolution with less rework.

Templates also make it easier to compare problems over time, track recurring issues, and evaluate the effectiveness of corrective actions.

Step-by-Step Guide: How to Create a Root Cause Analysis Template

Your RCA template should mirror the stages of an effective problem-solving process. Below are the 9 essential sections every template should include:

1. Define the Problem Clearly

Start with a precise problem statement. A vague description leads to scattered analysis.

- Example: “Production delay on Line A” (specific, measurable, observable).

2. Describe the Business Impact

Document how the problem affects operations, costs, or customers.

- Example: “Delay caused a 20% reduction in daily output and missed two client deadlines.”

3. Gather Data and Evidence

Base your analysis on facts, not assumptions.

- Collect logs, timelines, machine data, or incident reports.

- Example: “Machine stopped at 2 PM; downtime lasted 4 hours.”

4. Identify Possible Causes

Brainstorm potential contributors. Use RCA tools like:

- 5 Whys

- Fishbone Diagram (Cause-and-Effect Diagram)

- Pareto Chart

👉 Related reading: 7 Root Cause Analysis Tools and Techniques

5. Analyze and Prioritize Root Causes

Evaluate data to confirm the true root cause(s). Avoid stopping at surface-level findings.

- Example: “Root cause: scheduled maintenance missed due to understaffing.”

6. Develop Corrective Actions

Propose actionable, realistic solutions that directly address the root cause.

- Example: “Hire one additional maintenance technician and set up an automated maintenance alert system.”

7. Assign Responsibilities

Document who is responsible for each action.

- Example: “Maintenance Manager: oversee scheduling system setup.”

8. Set Timelines for Implementation

Establish deadlines to keep actions on track.

- Example: “New hire completed within 30 days; scheduling software live in 14 days.”

9. Monitor and Follow Up

Track results and validate effectiveness. Continuous monitoring ensures solutions actually work.

- Example: “Review downtime reports weekly for 3 months to confirm reduced stoppages.”

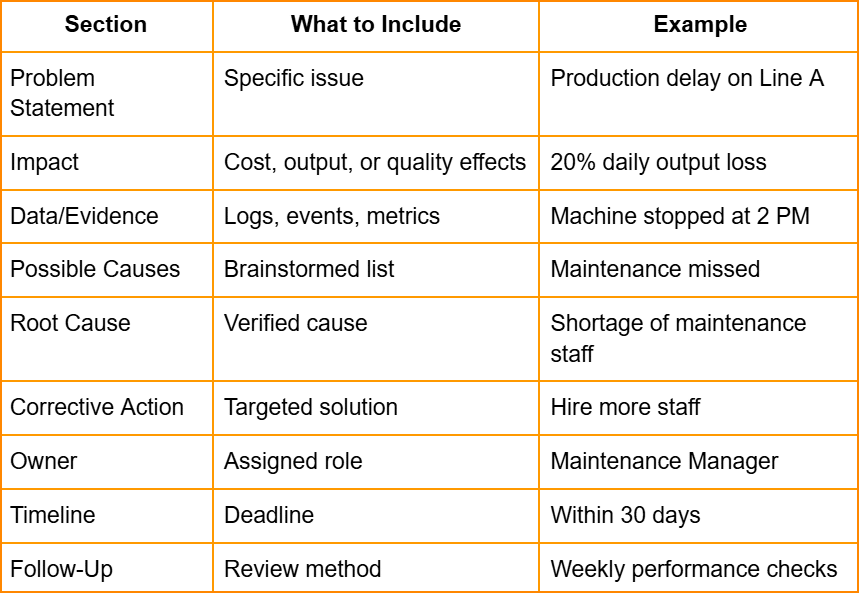

Example Root Cause Analysis Template Structure

Here’s a simple format your team can adopt:

Pro Tips for Building Effective RCA Templates

- Keep it visual: Use diagrams and tables for clarity.

- Standardize across teams: Templates should be adaptable but consistent.

- Leverage software: Tools like EasyRCA make it easy to capture, analyze, and report RCA findings in one place.

- Review regularly: Update templates as your organization’s processes evolve.

FAQs About RCA Templates

Q: Can I use the same RCA template across different industries?

Yes. While details vary, the framework is universal.

Q: What’s the difference between an RCA template and an RCA tool?

A template is a structured form; a tool (like EasyRCA) automates and streamlines the process.

Q: Should I always use multiple RCA techniques (5 Whys, Fishbone, etc.)?

Not always—but combining techniques often gives a more complete picture.

Take the Guesswork Out of Problem-Solving

A well-structured root cause analysis template empowers organizations to solve problems systematically, prevent repeat issues, and improve performance. By following this step-by-step guide, you’ll ensure your team consistently addresses root causes—not just symptoms.

Ready to take your RCA process further?

👉 Streamline your RCA with EasyRCA—our software helps teams move faster, capture insights, and deliver measurable results.

Ignite your curiosity, subscribe now!

Stay informed and connected with the latest updates by subscribing today!

Recent Comments