With over two decades in business – spanning strategy consulting, tech startups and executive leadership – I am committed to helping your organization thrive.

At Reliability, we’re on a mission to help enhance strategic decision-making and operational excellence through the power of Root Cause Analysis, and I hope this article will be helpful!

Our goal is to help you better understand advantages and limitations of 5 Whys vs. Fishbone techniques by offering insights and practical tips based on years of experience. Whether you’re new to doing RCAs or a seasoned pro, we trust this will be useful in your journey towards working hard and working smart.

_________________

Among the various RCA techniques, the 5 Whys and Fishbone Diagram are widely used. Each of these tools have their use cases and limitations. This article delves into these two methods, highlighting their limitations and contrasting their applications in quality management.

Understanding the 5 Whys and Fishbone Diagram

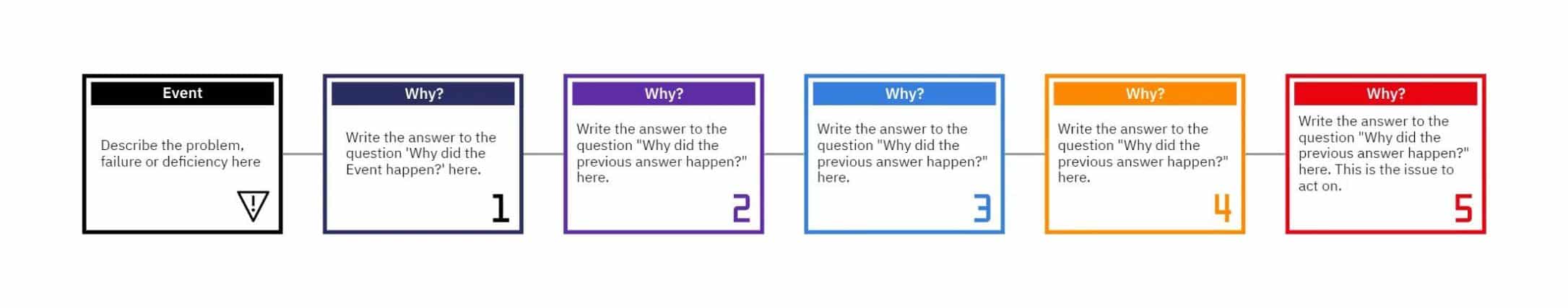

The 5 Whys Method

The 5 Whys is a straightforward approach, involving the repetitive asking of ‘why’ to peel back the layers of an issue. It’s akin to a detective methodically questioning to get to the heart of the matter. This simplicity, however, comes with its own set of limitations. We have discussed 5 Whys technique in detail here.

Advantages of the 5 Whys

- Simplicity and Ease of Use : The 5 Whys method is simple to understand and apply. It doesn’t require specialized training or complex tools, making it accessible to a wide range of users.

- Quick Identification of Root Causes: Due to its straightforward nature, the 5 Whys can quickly drill down to the root cause of a problem, making it efficient for time-sensitive analyses.

- Cost-Effectiveness: Minimal Resources Required: This method doesn’t necessitate extensive resources or tools, making it a cost-effective option for many organizations.

- Encourages Deep Thinking: Promotes Investigative Analysis: By repeatedly asking ‘why’, the method encourages deeper thinking and exploration beyond surface-level symptoms.

- Flexibility: Adaptable Across Various Problems: The 5 Whys can be applied to a wide range of issues, from simple operational glitches to more complex organizational problems.

Limitations of the 5 Whys

- Oversimplification: The method can be too basic for complex problems, potentially overlooking deeper, systemic issues.

- Subjectivity and Bias: The effectiveness of the 5 Whys heavily relies on the individual’s insight conducting the analysis. This can lead to biased conclusions if the investigator’s perspective is limited.

- Lack of Replicability: Different individuals may arrive at different root causes for the same problem, questioning the reliability and consistency of the method.

- Inadequate for Complex Problems: The 5 Whys may not effectively address multifaceted issues where multiple, interrelated causes exist.

The Fishbone Diagram

Also known as the Ishikawa or cause-and-effect diagram, the Fishbone Diagram allows for a more structured analysis, categorizing potential causes of problems.

Advantages of the Fishbone Diagram:

- Comprehensive Analysis: The Fishbone Diagram allows for a more detailed and comprehensive exploration of potential causes of a problem. It provides a visual map of causes and their subcategories, enhancing understanding and communication among team members.

- Facilitates Team Collaboration: The Fishbone Diagram is an excellent tool for brainstorming sessions, promoting collaboration and collective problem-solving. It allows for the inclusion of multiple viewpoints, leading to a more rounded analysis.

- Categorization of Causes: The method helps in systematically categorizing different causes, making it easier to identify areas for improvement. Unlike the 5 Whys, the Fishbone can uncover several root causes, particularly useful in complex scenarios with interrelated issues.

- Versatility: The Fishbone Diagram can be adapted to a wide range of sectors, from manufacturing to service industries.

- Enhances Problem-Solving Skills: Working with the Fishbone Diagram can enhance the analytical and critical thinking skills of team members.

Limitations of the Fishbone Diagram

- Complexity and Overwhelming Data: The Fishbone can become convoluted, especially when dealing with intricate problems, leading to information overload.

- Risk of Digression: The broad scope of the Fishbone Diagram can sometimes lead to a loss of focus, as teams might get sidetracked by less relevant causes.

- Categorisation Challenges: Deciding how to categorise different causes can be subjective, potentially leading to important issues being overlooked.

How do 5 Whys and Fishbone Diagrams Differ in Quality Management?

Application in Complex Scenarios

While the 5 Whys is adept at drilling down to the root of a single issue, the Fishbone Diagram excels in situations where multiple causes intertwine. The Fishbone’s categorisation aids in visualizing the relationship between different factors, whereas the 5 Whys can oversimplify these connections.

Collaboration and Stakeholder Involvement

The Fishbone Diagram is particularly effective in collaborative environments, encouraging input from various stakeholders. This contrasts with the 5 Whys, which can be limited by the knowledge and perspective of the individual leading the analysis.

Depth vs Breadth of Analysis

The 5 Whys is a deep dive into a single line of inquiry, potentially missing out on the breadth of analysis that the Fishbone Diagram offers with its multi-angled approach.

Conclusion

Both the 5 Whys and Fishbone Diagram have their place in root cause analysis and the choice between them depends on the complexity of the problem, the need for collaborative input, and the depth of analysis required. Understanding their limitations is key to selecting the right tool for effective problem-solving in quality management. While neither method is a one-size-fits-all solution, their strategic application can significantly enhance the problem-solving process.

___________

I hope you found this guide to advantages and limitations of 5 Whys vs. Fishbone techniques insightful and actionable! Stay tuned for more thought-provoking articles as we continue to share our knowledge. Success is rooted in a thorough understanding and consistent application, and we hope this article was a step in unlocking the full potential of Root Cause Analysis for your organization.

Reliability runs initiatives such as an online learning center focused on the proprietary PROACT® RCA methodology and EasyRCA.com software. For additional resources, visit EasyRCA Resources.

Ignite your curiosity, subscribe now!

Stay informed and connected with the latest updates by subscribing today!